LS Cam Bearing Challenges

By Mike Mavrigian Replacing cam bearings in a factory LS block can be easy, or it can turn into a can of worms. Granted, this article likely will not answer all questions or address every possible issue, but we’ll make …

Camshaft Grinding

By Andy Kennedy In 1941, Jack Engle built one of the first known cam grinders. He used a bench top lathe, a tool post grinder and a homemade rocking table to make the grinder. Today, cam grinders are more advanced …

Seven Easily Avoidable Engine Rebuild Mistakes

By Charles Navarro and Jake Raby Even when using the best quality engine parts, you cannot always guarantee success. It doesn’t matter if you are a novice or professional, we see easily avoidable mistakes on an almost daily basis in …

Vacuum Gauge Testing… Electronically?

By Chris Hamann Years ago, the vacuum gauge was standard in the diagnostic process. We were taught how to identify engines that had mechanical issues by analyzing the gauge’s needle. We also used a vacuum gauge to adjust the carburetor’s …

Looking Fresh

Moving forward with AERA’s Online and Hands-on Training Programs By Rob Munro Engine technology is changing at lightning speeds and so is the training needed to stay ahead. As the preeminent technical resource and industry voice for internal combustion engine …

Diesel Engine Diagnosis, Part 1

Looking for better clues By Francisco Aristizabal Engine diagnostics procedures are often the greatest challenge when trying to solve a diesel engine failure. When hard parts are involved, i.e., head, block, etc., sometimes some symptoms can be misleading, and cause …

The Missing Step in Rebuilding a Heavy-Duty Diesel Engine

By Steve Scott Great job, you have tightened the last bolts and fittings on your freshly rebuilt engine. It is filled with coolant and oil and ready to run, but if you miss the next step, you may be very …

Prosis Pro is Bursting with New Engines

By Rob Munro Rolling into 2025, AERA’s Prosis Pro Engine Specification Software is now loaded with over 15,000 engines. As the leader in supplying technical engine specifications and information, our plan is to add 1,000 new engine listings to Prosis …

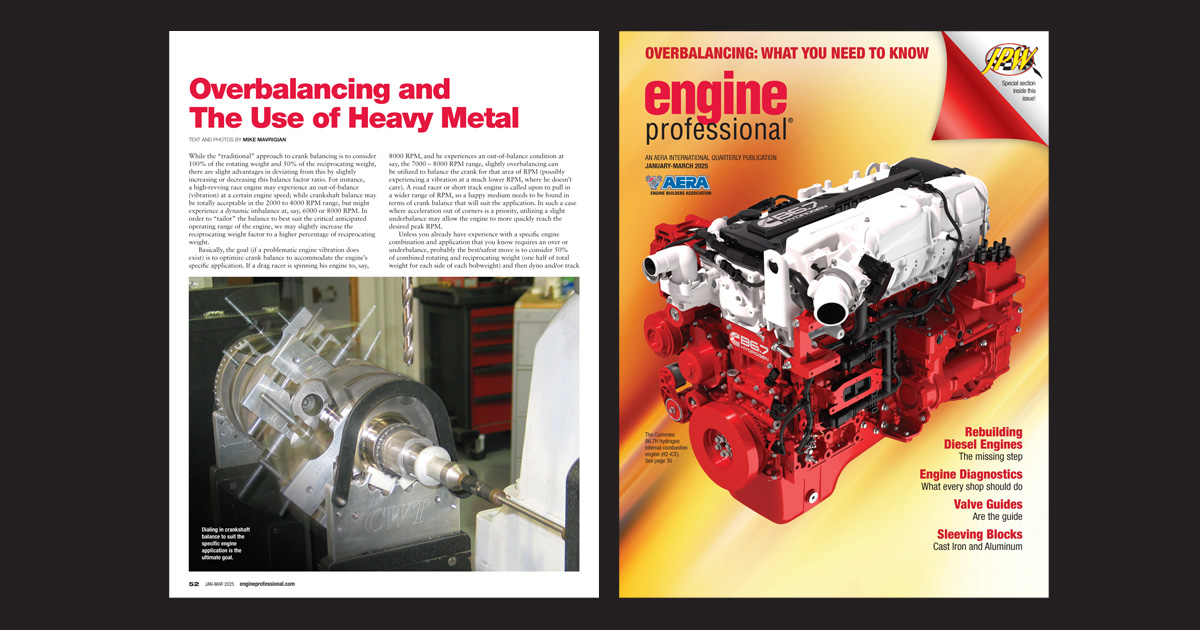

Overbalancing and The Use of Heavy Metal

By Mike Mavrigian While the “traditional” approach to crank balancing is to consider 100% of the rotating weight and 50% of the reciprocating weight, there are slight advantages in deviating from this by slightly increasing or decreasing this balance factor …

Sleeving Aluminum and Cast Iron Blocks

By Brian Roberts Machine shops are continually asked to help salvage engine blocks. This leads to the need to sleeve an aluminum or cast iron block. This information should be used anytime salvage operations are being performed on gas or …

Shop Supplies

By Andy Kennedy Shop supplies are a necessary component of any service or repair. Make sure you’re covered. When it comes to shop supplies, the cost of these items is often absorbed by many shops not realizing just how much …

Cummins Hydrogen 6.7L Engine

By Brian Roberts Cummins has released a new version of the 6.7L engine found in many trucks today. This hydrogen engine was developed to offer cleaner burning fuel for emissions on trucks and pieces of equipment. Europe is rapidly transitioning …

Engine Diagnostics

What every shop should consider By Chris Hamann How many times has a customer dropped off a cylinder head at your machine shop stating that it has a misfire. You go through the head, give it back to the customer, …

Improving Productivity and Quality with the 5S System

By Fernando Curello The need for better and more consistent productivity, quality and overall business results have been the motivation for the automotive manufacturing industry for more than 100 years. There is no doubt that the improved production systems and …