By Rob Munro

As engine builders, we’re always looking for new ways to do things more efficiently to save money. But what about a few tricks to help take the headache factor out of some of those jobs we do? That would be cool! (No pun intended!) Liquid Nitrogen (LN2) might just be one of those tricks.

Who hasn’t installed a cylinder sleeve, a pin bushing, or even a valve guide just to have it stick on you halfway through the process, this is not only frustrating, but can ruin a good part. Quickly freezing to shrink these normally press fit components before installing them is going to help save time and aggravation. Using LN2 might seem like a scary thought at first, but it can be easier and safer to use than you think.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=72

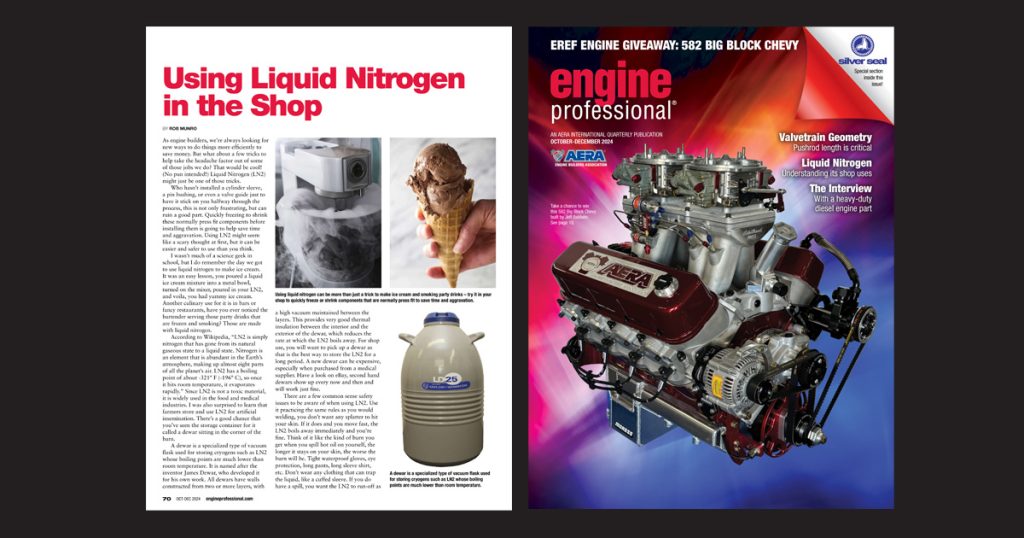

I wasn’t much of a science geek in school, but I do remember the day we got to use liquid nitrogen to make ice cream. It was an easy lesson, you poured a liquid ice cream mixture into a metal bowl, turned on the mixer, poured in your LN2, and voila, you had yummy ice cream. Another culinary use for it is in bars or fancy restaurants, have you ever noticed the bartender serving those party drinks that are frozen and smoking? Those are made with liquid nitrogen.

According to Wikipedia, “LN2 is simply nitrogen that has gone from its natural gaseous state to a liquid state. Nitrogen is an element that is abundant in the Earth’s atmosphere, making up almost eight parts of all the planet’s air. LN2 has a boiling point of about -321° F (-196° C), so once it hits room temperature, it evaporates rapidly.” Since LN2 is not a toxic material, it is widely used in the food and medical industries. I was also surprised to learn that farmers store and use LN2 for artificial insemination. There’s a good chance that you’ve seen the storage container for it called a dewar sitting in the corner of the barn.

A dewar is a specialized type of vacuum flask used for storing cryogens such as LN2 whose boiling points are much lower than room temperature. It is named after the inventor James Dewar, who developed it for his own work. All dewars have walls constructed from two or more layers, with a high vacuum maintained between the layers. This provides very good thermal insulation between the interior and the exterior of the dewar, which reduces the rate at which the LN2 boils away. For shop use, you will want to pick up a dewar as that is the best way to store the LN2 for a long period. A new dewar can be expensive, especially when purchased from a medical supplier. Have a look on eBay, second hand dewars show up every now and then and will work just fine.

There are a few common sense safety issues to be aware of when using LN2. Use it practicing the same rules as you would welding, you don’t want any splatter to hit your skin. If it does and you move fast, the LN2 boils away immediately and you’re fine. Think of it like the kind of burn you get when you spill hot oil on yourself, the longer it stays on your skin, the worse the burn will be. Tight waterproof gloves, eye protection, long pants, long sleeve shirt, etc. Don’t wear any clothing that can trap the liquid, like a cuffed sleeve. If you do have a spill, you want the LN2 to run-off as quickly as possible.

These last two rules are very important:

- Never seal LN2 in a closed container, the pressure will rise and could explode.

- Always use LN2 in a large open area. Since it expands by 700 times in volume when it vaporizes, it will displace the oxygen and there is a chance it could suffocate you. Very rare, but apparently it has happened.

One of the easiest ways to freeze the components that most engine builders work on is to grab yourself a good quality Styrofoam cooler. Simply pour the LN2 from the dewar into the cooler, then place the component you want to freeze into the liquid. These coolers work great because the foam will cause less liquid nitrogen to boil when it’s filled, they also work perfectly because the Styrofoam accumulates less frost. This results to less LN2 consumed, and I’ve even heard of shops pouring the unused LN2 back into the dewar when they are finished the job to save for another time.

In most cases, shrink fitting offers an easier solution than trying to heat up an outer component, especially when it comes to cylinder sleeve installation. I used to always cringe when we had to pound in a sleeve because we didn’t have any another option, having the sleeve stick or worse yet crack was always a day wrecker. The same can be said for valve guide installation in some aluminum heads. Pre-heating the head and throwing the valve guides in the freezer is time consuming, LN2 could make these kinds of jobs easier and a little less of a headache. Most of the suppliers that shops use to purchase their welding gas from can supply LN2. With the right storage container and a little practice, this may be the smoking gun you’re looking for.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=72