Where does the pressure go?

By Chuck Lynch

Anyone with much experience diagnosing oil pressure complaints knows that pressure is restriction to FLOW. It goes back to the old experiment of holding your finger over the garden hose. The flow is high, and the pressure is low until you try to plug the stream of flow with your thumb, and you can now spray water a much greater distance. That is easy enough to understand but finding the source of the leakage internally within an engine can be a real challenge. Today, the reality is that there may be a single source or multiple sources causing you grief.

I know that this was the topic that was really the root cause that we were discussing in my recent article about align boring cam bearings. That did steer some questions and comments my way and I want to expand on the challenges that we are faced with when working with modern engines.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ3/#p=66

As engines have evolved, the lubrication system has become more than lubrication to sliding components. The lubrication system has become integral in the engine management system to a level that far exceeds just the good old hydraulic lifters. Today, with camshaft phasing, variable geometry rockers, cylinder deactivation systems, variable geometry turbos and so on, we have to pay closer attention to oil clearances and part fitment more than ever before.

There was a time that it did not matter much to polish a cam or a crank below the minimum specification by .0005″ (.0012mm). The problem with that today is almost everything has multiple cams, controlling the previously mentioned devices and the light oils, the risk of low oil pressure complaints is higher. A little extra polish here and there can result in excessive leakage. Sure, the adjustments seem minimal to the part you are adjusting but the number of interfaces is high. Say 25 bearing journals instead of what used to be 10. You get the drift. A lot of little taps can do the same damage as one big blow.

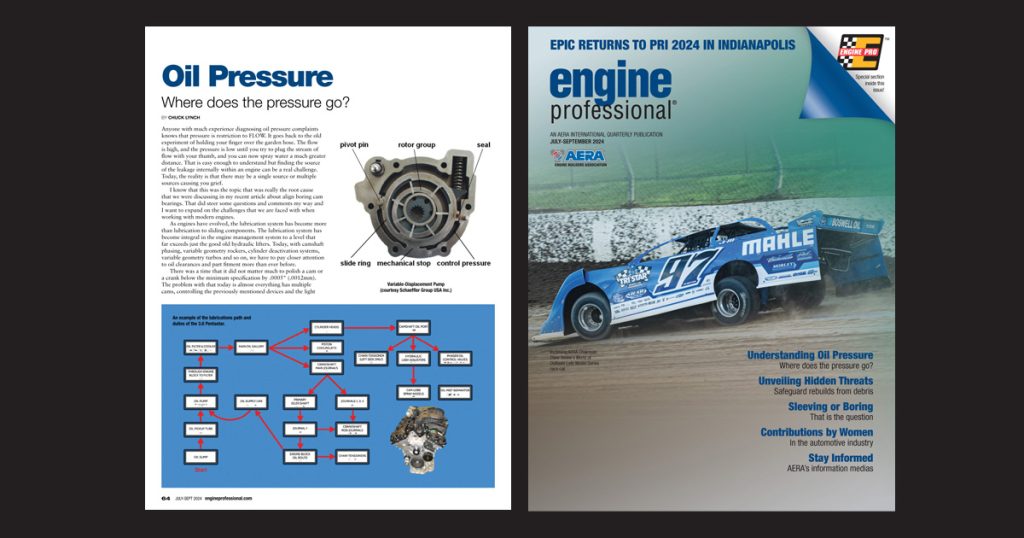

That has been a challenge at the OE level as well and that is what drove the development of variable displacement oil pumps to accommodate needed changes for engines at cold start up, high load, low load or hot idle.

That is a nice option for modern engine designs, but we cannot just retrofit this technology to earlier design engines. Even if you could bolt the part to the engine, you would not have the system to communicate the need to the pump to manage it.

Shown on the previous page is an example of the lubrications path and duties of the 3.6 Pentastar. Again, as stated earlier, the oil is not just providing sliding friction protection but hydraulically controlling movement, cooling pistons, actuates rocker ratio and more.

So, what does all of this mean to the machine shop? We take a lot of calls in which the conversation is trying to determine why a customer would have low oil pressure. The machine shop may not have assembled the engine but if they machined a part, it has to be the cause of low oil pressure, right? I am only kidding but you know that you will get challenged by the builder, installer or maybe the end user as too why the oil pressure is different. If you are armed with some data to better ask questions that are relevant to the impact on pressure and flow, you can possibly train your customers to question parts that they plan to reuse.

Here is a more modern example for the gas/petrol engine market and pretty much old news for diesel engines. A commonly misunderstood part is the piston cooling jets. These are being removed and reinstalled without any validation of functionality. Sometimes they are missing washer seats, or the check valve assembly is not functional. This may be one or all of the cooling jets that are a problem. If you have a couple of leaking piston cooling jets, idle pressure will suffer.

These types of challenges have driven more engine builders to use engine test systems like RMC offers that can qualify pressure and flow while also controlling cam phasing, specific crank orientation where bearing eccentricity can be evaluated and other circuit losses. This process can be used for reverse engineering as well as a final inspection. When you can see the leak and put a number to the volume of the leak you can make corrections.

To summarize, the best way to address low idle oil pressure issues is to consider the lubrication systems design. Adhere to the dimensional tolerances/clearances that are documented. Do not try to cover the symptoms with the wrong oil because it could cause latency in the function of solenoid valves, phasers and so on, which is exchanging one problem for another.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ3/#p=66