By Andy Kennedy

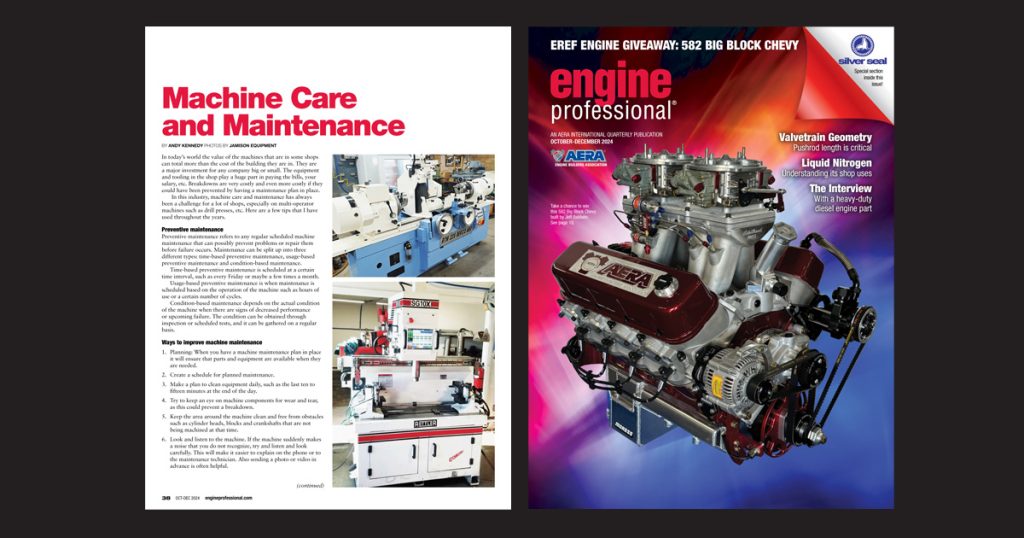

In today’s world the value of the machines that are in some shops can total more than the cost of the building they are in. They are a major investment for any company big or small. The equipment and tooling in the shop play a huge part in paying the bills, your salary, etc. Breakdowns are very costly and even more costly if they could have been prevented by having a maintenance plan in place.

In this industry, machine care and maintenance has always been a challenge for a lot of shops, especially on multi-operator machines such as drill presses, etc. Here are a few tips that I have used throughout the years.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=40

Preventive maintenance

Preventive maintenance refers to any regular scheduled machine maintenance that can possibly prevent problems or repair them before failure occurs. Maintenance can be split up into three different types: time-based preventive maintenance, usage-based preventive maintenance and condition-based maintenance.

Time-based preventive maintenance is scheduled at a certain time interval, such as every Friday or maybe a few times a month.

Usage-based preventive maintenance is when maintenance is scheduled based on the operation of the machine such as hours of use or a certain number of cycles.

Condition-based maintenance depends on the actual condition of the machine when there are signs of decreased performance or upcoming failure. The condition can be obtained through inspection or scheduled tests, and it can be gathered on a regular basis.

Ways to improve machine maintenance

- Planning: When you have a machine maintenance plan in place it will ensure that parts and equipment are available when they are needed.

- Create a schedule for planned maintenance.

- Make a plan to clean equipment daily, such as the last ten to fifteen minutes at the end of the day.

- Try to keep an eye on machine components for wear and tear, as this could prevent a breakdown.

- Keep the area around the machine clean and free from obstacles such as cylinder heads, blocks and crankshafts that are not being machined at that time.

- Look and listen to the machine. If the machine suddenly makes a noise that you do not recognize, try and listen and look carefully. This will make it easier to explain on the phone or to the maintenance technician. Also sending a photo or video in advance is often helpful.

Implementing machine maintenance at work

Machine maintenance is very important to any business, particularly those that are very dependent on machines for operation on a daily basis. Without adequate machine maintenance strategies in place, it can be very costly for shops and companies.

Regardless of the type of maintenance your team utilizes, different areas of the shop must be regularly serviced in order to avoid costly repairs and down time. The knowledge and skills of the operator must be regularly maintained and updated as well so they don’t fall behind.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=40