By Brian Roberts

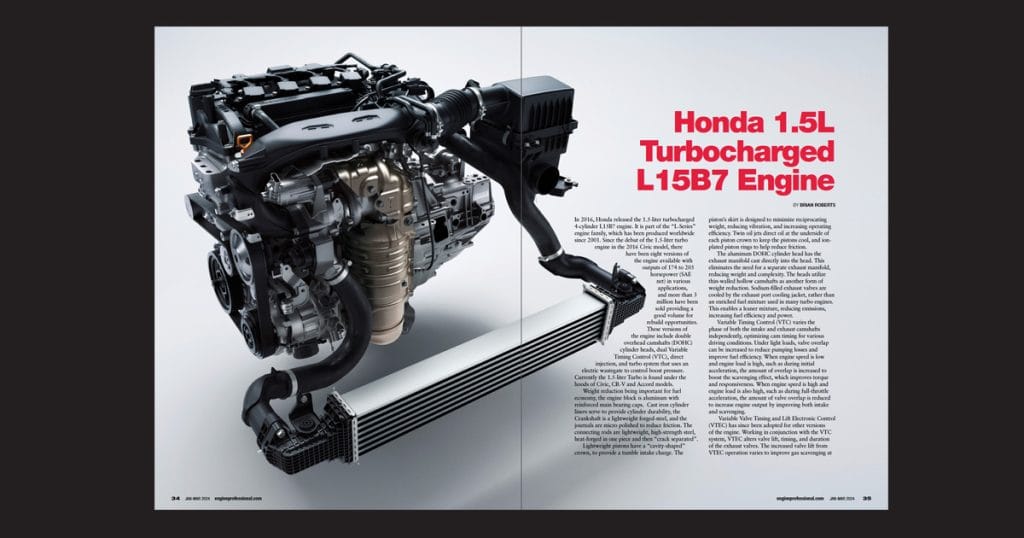

In 2016, Honda released the 1.5-liter turbocharged 4-cylinder L15B7 engine. It is part of the “L-Series” engine family, which has been produced worldwide since 2001. Since the debut of the 1.5-liter turbo engine in the 2016 Civic model, there have been eight versions of the engine available with outputs of 174 to 205 horsepower (SAE net) in various applications, and more than 3 million have been sold providing a good volume for rebuild opportunities.

These versions of the engine include double overhead camshafts (DOHC) cylinder heads, dual Variable Timing Control (VTC), direct injection, and turbo system that uses an electric wastegate to control boost pressure. Currently the 1.5-liter Turbo is found under the hoods of Civic, CR-V and Accord models.

Weight reduction being important for fuel economy, the engine block is aluminum with reinforced main bearing caps. Cast iron cylinder liners serve to provide cylinder durability, the Crankshaft is a lightweight forged-steel, and the journals are micro polished to reduce friction. The connecting rods are lightweight, high-strength steel, heat-forged in one piece and then “crack separated”.

Lightweight pistons have a “cavity-shaped” crown, to provide a tumble intake charge. The piston’s skirt is designed to minimize reciprocating weight, reducing vibration, and increasing operating efficiency. Twin oil jets direct oil at the underside of each piston crown to keep the pistons cool, and ion-plated piston rings to help reduce friction.

The aluminum DOHC cylinder head has the exhaust manifold cast directly into the head. This eliminates the need for a separate exhaust manifold, reducing weight and complexity. The heads utilize thin-walled hollow camshafts as another form of weight reduction. Sodium-filled exhaust valves are cooled by the exhaust port cooling jacket, rather than an enriched fuel mixture used in many turbo engines. This enables a leaner mixture, reducing emissions, increasing fuel efficiency and power.

Variable Timing Control (VTC) varies the phase of both the intake and exhaust camshafts independently, optimizing cam timing for various driving conditions. Under light loads, valve overlap can be increased to reduce pumping losses and improve fuel efficiency. When engine speed is low and engine load is high, such as during initial acceleration, the amount of overlap is increased to boost the scavenging effect, which improves torque and responsiveness. When engine speed is high and engine load is also high, such as during full-throttle acceleration, the amount of valve overlap is reduced to increase engine output by improving both intake and scavenging.

Variable Valve Timing and Lift Electronic Control (VTEC) has since been adopted for other versions of the engine. Working in conjunction with the VTC system, VTEC alters valve lift, timing, and duration of the exhaust valves. The increased valve lift from VTEC operation varies to improve gas scavenging at low rpm, part throttle conditions, as well as higher rpm, full throttle operation, helping to improve performance across the engine speed range.

The engine uses a high-pressure direct-injection system, a direct-injection pump with variable pressure control helps to optimize injector operation. The multi-hole injectors deliver fuel directly into each cylinder, optimizing fuel atomization for more efficient combustion. These multi-hole injectors can create the ideal stoichiometric fuel/air mixture in the cylinders for good emissions and adjusting its function for the best performance based on operating conditions.

For maximum responsiveness, a small-diameter turbo is used. The single-scroll housing design helps the turbo build boost even at relatively small throttle openings and low engine speeds. The electrically actuated wastegate enables precise control of boost pressure.

Cooling the intake charge is a large low-restriction intercooler, in all cases it is positioned low in the front of the car where it receives essentially unobstructed airflow when the vehicle is in motion. As intake air is compressed by the turbo, it heats up, and the intercooler helps reduce that temperature, making it denser and improving performance. Lightweight resin composite inlet pipes carry air to and from the intercooler to reduce the overall weight of the turbo system.

Honda and other manufacturers are focusing on smaller displacement engines for fuel efficiency combined with turbochargers for performance enhancement. This continues and looks to be the standard going forward.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ1/#p=36