By Brian Roberts

AFM (Active Fuel Management) was introduced in 2007 for the GM LS engine platform. This cylinder deactivation system shuts down 4 of the 8 cylinders on an LS to reduce fuel consumption. The system is controlled by a combination of ECM, electrical signals, solenoids and oil pressure.

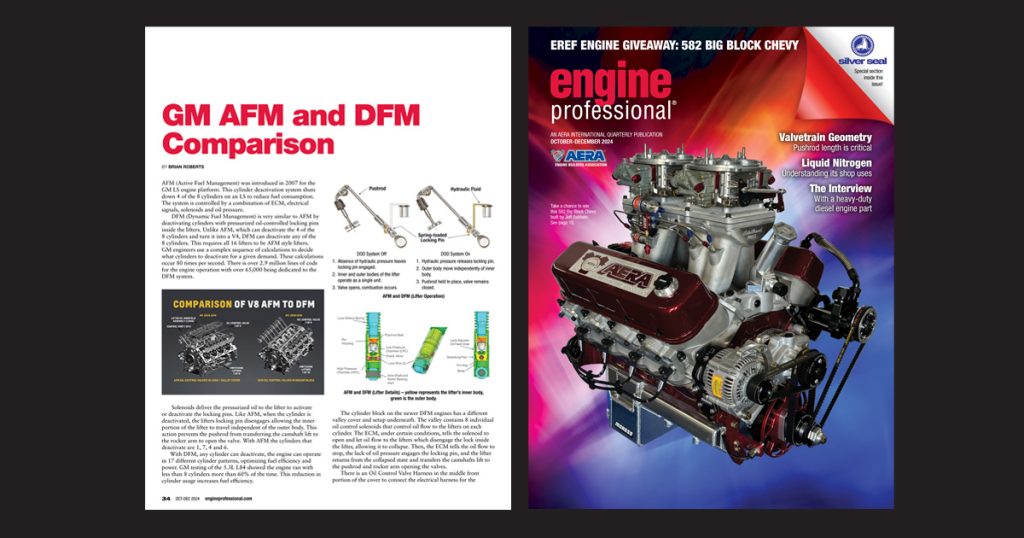

DFM (Dynamic Fuel Management) is very similar to AFM by deactivating cylinders with pressurized oil-controlled locking pins inside the lifters. Unlike AFM, which can deactivate the 4 of the 8 cylinders and turn it into a V4, DFM can deactivate any of the 8 cylinders. This requires all 16 lifters to be AFM style lifters.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=36

GM engineers use a complex sequence of calculations to decide what cylinders to deactivate for a given demand. These calculations occur 80 times per second. There is over 2.9 million lines of code for the engine operation with over 65,000 being dedicated to the DFM system.

Solenoids deliver the pressurized oil to the lifter to activate or deactivate the locking pins. Like AFM, when the cylinder is deactivated, the lifters locking pin disengages allowing the inner portion of the lifter to travel independent of the outer body. This action prevents the pushrod from transferring the camshaft lift to the rocker arm to open the valve. With AFM the cylinders that deactivate are 1, 7, 4 and 6.

With DFM, any cylinder can deactivate, the engine can operate in 17 different cylinder patterns, optimizing fuel efficiency and power. GM testing of the 5.3L L84 showed the engine ran with less than 8 cylinders more than 60% of the time. This reduction in cylinder usage increases fuel efficiency.

The cylinder block on the newer DFM engines has a different valley cover and setup underneath. The valley contains 8 individual oil control solenoids that control oil flow to the lifters on each cylinder. The ECM, under certain conditions, tells the solenoid to open and let oil flow to the lifters which disengage the lock inside the lifter, allowing it to collapse. Then, the ECM tells the oil flow to stop, the lack of oil pressure engages the locking pin, and the lifter returns from the collapsed state and transfers the camshafts lift to the pushrod and rocker arm opening the valves.

There is an Oil Control Valve Harness in the middle front portion of the cover to connect the electrical harness for the solenoids. From a service viewpoint having the solenoids built into the unit like AFM requires replacement of the unit if one of the four solenoids is bad. DFM allows for replacement of just the one solenoid that is bad.

With DFM the cylinder deactivation lifters double from 8 to 16. AERA receives calls on these lifters failing, whether it is from lack of maintenance, like longer than normal oil change intervals or other reasons, If the failures do occur, it is a massive labor cost to repair.

Disabling the AFM or DFM systems with an OBD-II disabler is a choice many are making to stop the AFM or DFM function and leave it in full time V8 mode. Others are looking for a complete AFM or DFM delete kit to avoid any future issues. These choices are up to each individual owner and what is legal in their state.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ4/#p=36