Do yourself a favor!

By Rob Munro

So far, 2024 doesn’t seem any different than any other year that I can remember. Then I did the quick math and realized that it’s been 40 years since I started working full-time in an engine machine shop. Now, I could ramble on about how it seems like I’ve been working forever, or I only have…days until I retire. But when you love what you do, work doesn’t feel like a jail sentence. That’s what’s cool about the engine building industry, most of us are in it for the long haul because we thoroughly enjoy what we do. For that reason, taking the time to look after yourself when working in the shop will have big benefits as you get older.

I was lucky enough to land my dream job right out of high school, working in a shop I didn’t picture myself doing anything different. When I look back at those earlier years in the ’80s and ’90s, I wish I had taken more time in the shop to help myself with some better decisions regarding wearing gloves in the solvent tank, or using a mask to buff off cylinder heads, etc. The old timers were constantly on my butt reminding me to lift heavy things properly and yelling over to me, “Just wait until you’re my age.” But I guess it was my young and invincible attitude that probably got in the way of my listening skills. Workplace health and safety just wasn’t as much of a concern for me back then, especially in a small shop. This would have been the perfect time for me to start developing a few good habits so that they became routine later in my career.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ3/#p=74

Do I still have 10 fingers and 10 toes? Yes, I do! But I wish I had paid more attention to the little things like lifting techniques, posture while operating machines, skin and respiratory protection around chemicals and dust, as well as eye and ear protection. There are a few things going on with my body now that let me know that I could have done a better job with some of those health and safety techniques when I first started out.

I had a chance to sit down with Jasper Engines & Transmissions Corporate Care Manager, Jason Pieper, to discuss more about ways in which we can help ourselves regarding shop safety. Jason is a 27-year employee at Jasper and is directly involved in all their safety programs. The one thing that stood out for me when speaking with him was just how much they value their employees; THEY DO CARE, and even Jason’s title at Jasper emphasizes their philosophy on this topic. They believe in taking that short-term loss up front to take the time needed to get the safety training done right. This advice can also be applied to the small shop. Take the time to walk through each piece of equipment and let the employee know what is expected of them to stay safe.

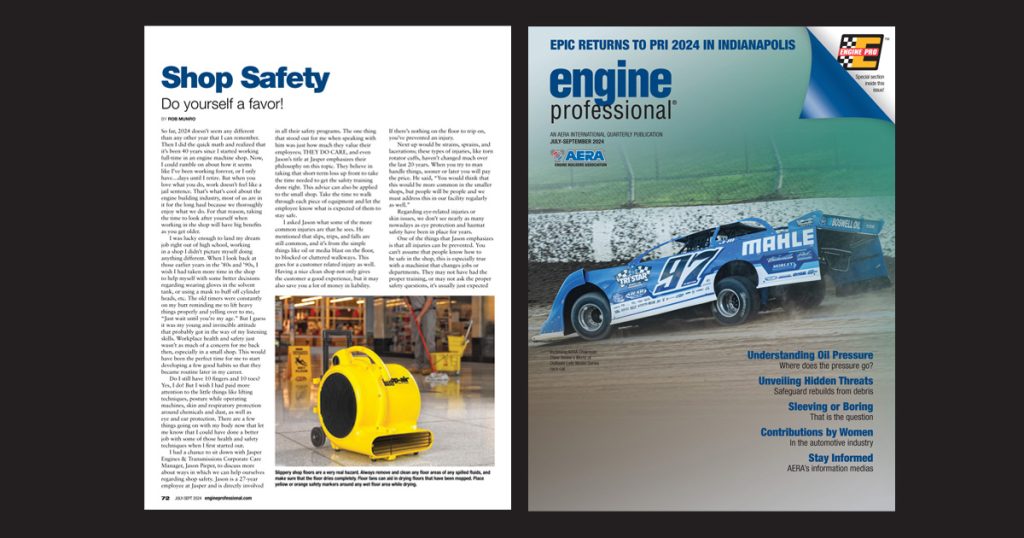

I asked Jason what some of the more common injuries are that he sees. He mentioned that slips, trips, and falls are still common, and it’s from the simple things like oil or media blast on the floor, to blocked or cluttered walkways. This goes for a customer related injury as well. Having a nice clean shop not only gives the customer a good experience, but it may also save you a lot of money in liability. If there’s nothing on the floor to trip on, you’ve prevented an injury.

Next up would be strains, sprains, and lacerations; these types of injuries, like torn rotator cuffs, haven’t changed much over the last 20 years. When you try to man handle things, sooner or later you will pay the price. He said, “You would think that this would be more common in the smaller shops, but people will be people and we must address this in our facility regularly as well.”

Regarding eye-related injuries or skin issues, we don’t see nearly as many nowadays as eye protection and hazmat safety have been in place for years.

One of the things that Jason emphasizes is that all injuries can be prevented. You can’t assume that people know how to be safe in the shop, this is especially true with a machinist that changes jobs or departments. They may not have had the proper training, or may not ask the proper safety questions, it’s usually just expected from a shop owner that they know. Having regular safety meetings is where some of these issues can get addressed. Shop owners need to take responsibility for laying out the groundwork, they set the standard for the training to be in place. It is up to the worker to value this training, follow it, and be accountable.

One of the things that Jason mentioned about new hires that I thought was cool is that Jasper developed a 12-session work conditioning program. Several times per week the employee works with an occupational therapist (OT) at the gym to help develop the physical training needed to perform on the job. Not only does it prepare them for the physical needs of the job, but the OT also gives supervisors feedback about the new hire’s listening skills and attitude towards the work.

Another body smart program that Jasper has implemented is a 3-4-minute stretch and flex routine at the start of each shift in the morning and then again after lunch. All departments gather in a circle to do the routine while instructions come over the intercom. This may sound silly but think how much better you would feel if you developed that into your daily schedule.

My final question to Jason was, “What words of wisdom are you offering to those folks that are just starting out in your company?”

He said, “The big thing is that we value you as a person, we need you here, and we care about you and your safety. In saying that, we are going to hold you accountable to a certain set of standards, if you break those rules then there will be consequences. We are also going to explain to you WHY it is so important to follow these guidelines. We have documented history, we know what can happen, injuries are both predictable and preventable. Safety must have a value for all of us, if you don’t value it then you will pay the price in the long run.”

Let’s face it, what you do now can affect you for the rest of your life. You’ve worked hard, why not go for the ultimate goal and live a happy and healthy retirement.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ3/#p=74