Bye-bye, pushrods!

By Brian Roberts

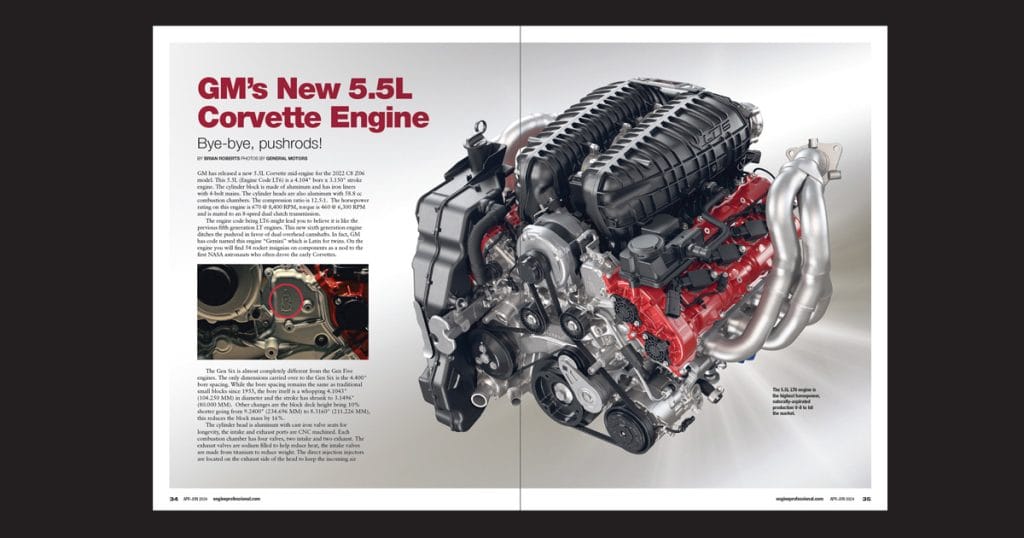

GM has released a new 5.5L Corvette mid-engine for the 2022 C8 Z06 model. This 5.5L (Engine Code LT6) is a 4.104″ bore x 3.150″ stroke engine. The cylinder block is made of aluminum and has iron liners with 4-bolt mains. The cylinder heads are also aluminum with 58.8 cc combustion chambers. The compression ratio is 12.5:1. The horsepower rating on this engine is 670 @ 8,400 RPM, torque is 460 @ 6,300 RPM and is mated to an 8-speed dual clutch transmission.

The engine code being LT6 might lead you to believe it is like the previous fifth generation LT engines. This new sixth generation engine ditches the pushrod in favor of dual overhead camshafts. In fact, GM has code named this engine “Gemini” which is Latin for twins. On the engine you will find 54 rocket insignias on components as a nod to the first NASA astronauts who often drove the early Corvettes.

The Gen Six is almost completely different from the Gen Five engines. The only dimensions carried over to the Gen Six is the 4.400″ bore spacing. While the bore spacing remains the same as traditional small blocks since 1955, the bore itself is a whopping 4.1043″ (104.250 MM) in diameter and the stroke has shrunk to 3.1496″ (80.000 MM). Other changes are the block deck height being 10% shorter going from 9.2400″ (234.696 MM) to 8.3160″ (211.226 MM), this reduces the block mass by 16%.

The cylinder head is aluminum with cast iron valve seats for longevity, the intake and exhaust ports are CNC machined. Each combustion chamber has four valves, two intake and two exhaust. The exhaust valves are sodium filled to help reduce heat, the intake valves are made from titanium to reduce weight. The direct injection injectors are located on the exhaust side of the head to keep the incoming air unobstructed as it enters the combustion chamber. The injectors have six spray holes accurately drilled into them with a laser to promote the optimal fuel mist pattern.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ2/#p=36

The camshafts use variable valve timing to provide optimal driving for around town or high RPM output. Valve timing can be adjusted up to 55° on the intake and up to 24° on the exhaust. The valve springs have inner and outer springs to help prevent valve floating at higher RPM’s. Each of the 32 valves in the engine use a shim to adjust valve lash. The factory checks the valve lash three times before it is installed into the vehicle. If adjustment of the lash becomes necessary removing the camshafts and replacing the shim will be required, but GM claims this original lash setting should last the life of the engine as endurance testing showed no meaningful wear to affect lash.

The crankshaft is forged steel and has transitioned to a “Flat” design, meaning the throws are 180° apart versus the traditional 90° apart or “Cross-Plane” design. The flat design is often used in racing and European supercars. What is old is new again, around 100 years ago Cadillac once used a flat-plane design but converted to the 90° to reduce vibrations. GM has returned to the flat design for some of the advantages it provides, like less rotating inertia. This design enables four exhaust strokes in both cylinder banks that are 180° apart. With the shorter stroke and connecting rods the crank counterweights are lighter reducing the rotating inertia. The flat-cranks 180° spacing allows for increased scavenging, this is where exhaust gas in a cylinder sucks exhaust gas out of an adjoining cylinders exhaust port. This helps with flow and efficiency. As with earlier GM flat-crank designs vibrations were an issue and testing revealed the frequency of the vibration was loosening the oil filter. A redesign of the filter, relocating inside a beefy aluminum canister solved that issue. To protect the plastic oil reservoir from vibration damage, it is mounted to the block with rubber isolators.

The cylinder block is a split design with the two halves coming together at the crankshaft centerline. Both halves are made of aluminum. A special talcum additive smooths surfaces in contact with coolant and oil. The liners are iron, and they are pressed in place, they are Siamese arranged and contact the adjoining liner, so coolant does not flow between them except small, drilled passages near the deck surface. The liners are deep frozen and slip into a hot block and rest on a small shelf in the bottom of the bore. The block then has a torque plate installed to simulate the stresses induced upon torquing the bolts and honed to finish size that provides a distortion free bore for good piston ring seal. There are 4 vertical bolts for each of the five main bearing caps. The intermediate shaft in between both cylinder banks and just above the crank is driven off a short crankshaft chain which drives a secondary chain that drives the camshafts on both banks. Lobes on the shaft drive two 5000 PSI fuel pumps and are in the valley of the engine. A separate chain on the nose of the crankshaft drives seven oil pumps, with one pump lubricating the main bearings, the cylinder oil squirters and the four camshafts. The others are used to evacuate the 4 sealed crankcase bays and drain down cavities which are located at the front and rear of the block.

There are cast in scrapers in the block that come in proximity to the flat-crank’s counterweights to scrape off oil. A partial vacuum is generated by this scavenging and reduces the windage losses created when the crank spins in the oil. Amazingly only a half quart of oil circulates in the engine at any time, even peak RPM. Connecting rods are made from forged titanium and sourced from Austria. The pistons are forged aluminum and have a very short skirt. The piston rings and cam followers have friction reducing coating made from a diamond like carbon.

The intake manifold for this engine needs to take in a large amount of air to help produce the 670 horsepower. The manifold sitting on top of the engine is a two-piece design injection molded glass filled nylon that is reinforced with ribbing for structural integrity. The manifold has two plenums, both combined for a volume of 5.5L, which is identical to the engine displacement. This makes the manifold very large. This is not an issue as the mid-engine design has the engine sitting low in the chassis behind the driver.

Each plenum contains four small trumpet shaped molded intake-port extensions and are fed by an 87MM throttle body. Two of those valves share a common shaft, opening and closing in sync. The third one operates independently. One valve opens at around 2000 RPM. The others open on a schedule that varies with driving mode and RPM. All valves close shortly before the engine’s 8400-RPM power peak. This increases the LT6’s torque curve from 3500 to 8600 RPM. The cylinders get greater-than-atmospheric air pressure when running and air volume 10% beyond piston displacement bringing the engine to 110% volumetric efficiency. Between these plenums are three servo-operated valves that adjust how the air resonates in the manifold, producing more torque through the rev range.

GM’s new design has achieved unheard of numbers for naturally aspirated V-8 engines. The estimated 0-60 mph number is 2.6 seconds. The next iteration of this engine coming down the pipeline is the 800 hp twin turbo version slated to be the LT7 and used in the ZR1 Corvette. The good old small block has come a long way since 1955. As more manufacturers are moving to small displacement engines with turbos, it is nice to see raw V-8 power still being offered for those who want it. Long live the small block.

Read this article with all images in the digital issue of Engine Professional magazine https://engineprofessional.com/2024EPQ2/#p=36